Machines & Capabilities

GK Machine uses CAD renderings, CNC programming, laser operations and quality control processes to produce the best possible product for our customers. With our state-of-the-art laser & plasma machines, we have the ability to make parts that are repeatable and accurate using the most common materials. Whether it’s a simple part or intricate piece, our multiple lasers and large plasma cutting table allows us to process both small and large productions, running fast, efficiently and accurately.

Designing from conception to production, our design engineers work with you to create custom parts or modify existing part for your project. Our CAD/CAM design center includes MasterCAM, AutoCAD and SolidWorks, enabling our team of design engineers to provide you with precision parts engineering and accurate time estimates of production for short run, prototype and long run production.

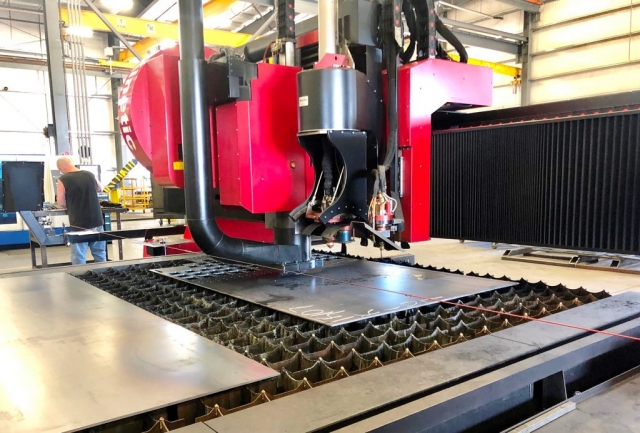

Kinetic K5000 XMC – Combination Drilling & Cutting

- Drill 4” diameter holes in 8” thick plate

- Plasma torch with production cutting of 2” mild steel

- Plasma and oxygen bevel cutting up to 45 degrees

- Maximum width of 10’ and maximum length of 40’

With two Trumpf lasers we have the ability to make parts that are repeatable and accurate. Trumpf laser help to ensure consistency from part to part with cleaner cutting. GK has special fixturing and prefabricated parts to help us achieve fast turnaround and meet delivery times.

GK offers fast and efficient services with our two Trumpf Liftmasters. They can automatically load and unload sheets of metal to and from the laser cutting machines – for lights-out operations. This enables GK to achieve faster and more efficient production runs.

(3) Trumpf Press Brakes Trubend (L3030, L3050 & 7036)

With GK’s hydraulic press brakes, they give another option when trying to shape metal. Our bending capability accomplishes this by bending steel at various angles to create different structures, parts and pieces. The press brake offers many more options when creating strong, non-welded parts and pieces. Since it’s computerized, the hydraulic machine controls can ensure the precision and accuracy to allow exact parts, pieces and structures.

Trumpf Trubend 7036 and 5320 PDFTrumpf Punch Press 260T

GK’s punch press is used to cut holes in material and can be used to push metal to form raised holes. Punching is the most cost effective process of making holes in steel metal. It is able to create multiple shaped holes, custom perforation, perforated and grating screens for processing machinery and heavy materials.

Trumpf 250T Punch PDFPlasma Drilling & Cutting Services

Advanced Plasma & Oxy Fuel Cutting

Enhanced Bevel & Multi-Torch Cutting

Advanced Drilling, Milling and More

Part making is another of our primary services and areas of expertise. GK can handle large sized metal sheets and plates (10’ x 40’). With high cutting speeds, precision drilling and easy material handling enables us to maximize production output.

This powerful machine can handle multiple functions in one pass:

- Thick Steel Cutting

- Part Marking

- Drilling

- Counter Boring

- Bevel Cutting

- Milling

Laser Cutting Services

Our expert laser design staff can assist you with laying out your project, while utilizing computerized control systems to ensure quality and consistency throughout the process.

- Lower Costs from Less Scrap

- Enhanced Consistency from Part to Part

- Cleaner Faster Cutting

- Special Fixture for Prefabricated Parts

- Etching on Most Materials

Forming & Punch Services

GK offers punching services and are able to create multiple shaped holes, custom perforation, perforated and grating screens for processing machinery and heavy metal materials.

Shipping Service

GK has a multitude of resources to offer customers with specialty crates, packaging and a seamless transportation process. GK takes responsibility for ensuring the safety of valuable items until they reach their intended destination through qualified carriers.

A wide range of shipping methods:

The GK team works with you to determine the best option for your shipment. We’ll help choose the option that meets your timeline and your budget.